Bespoke Wraps

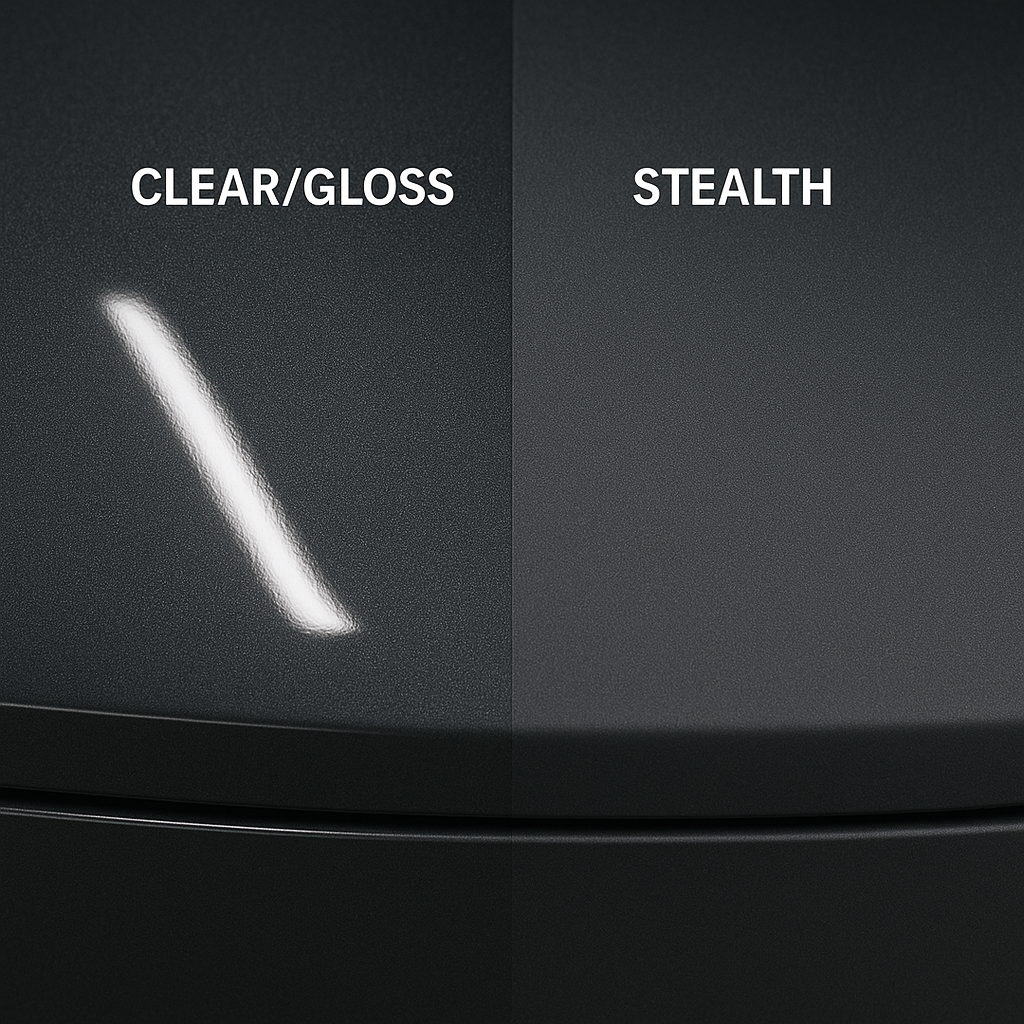

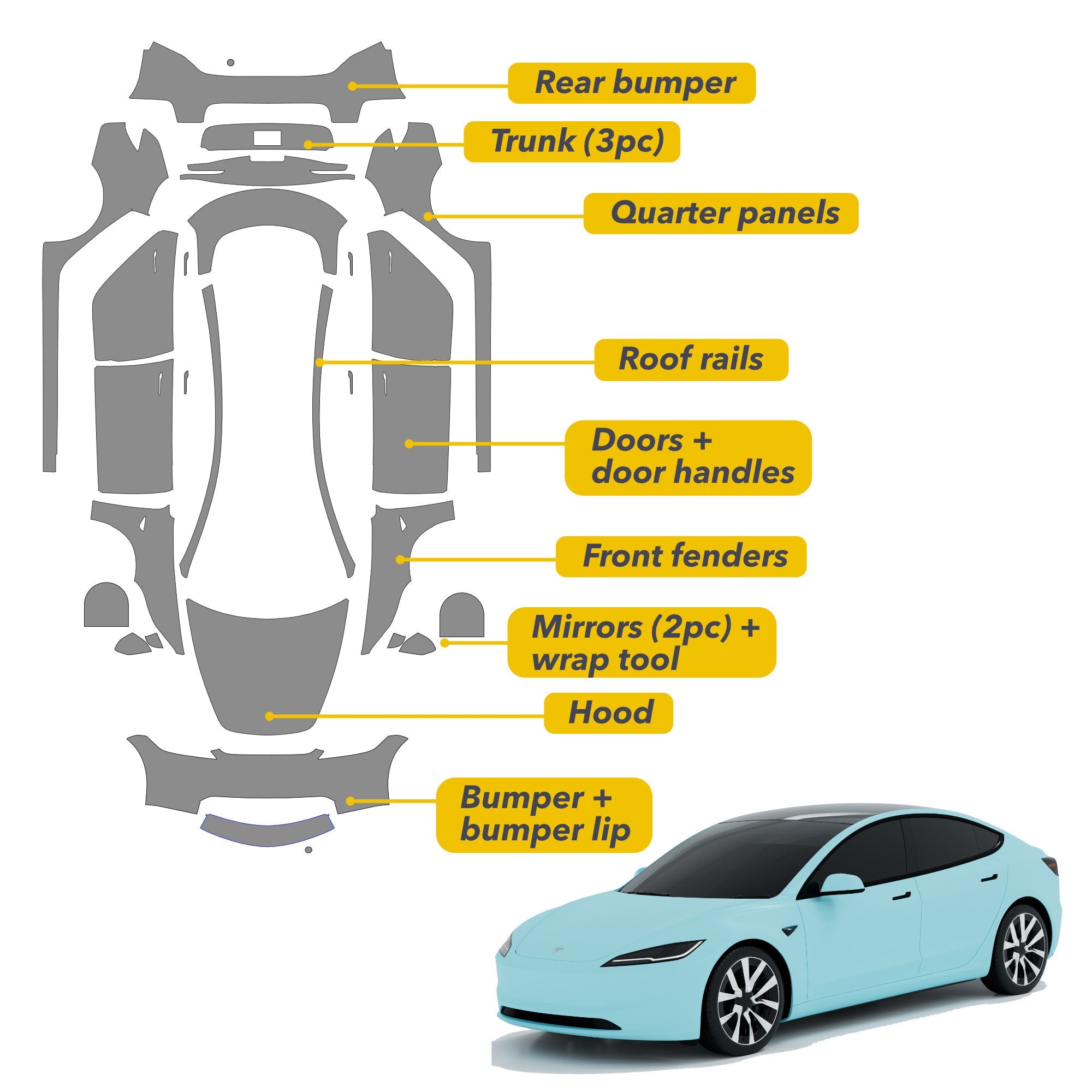

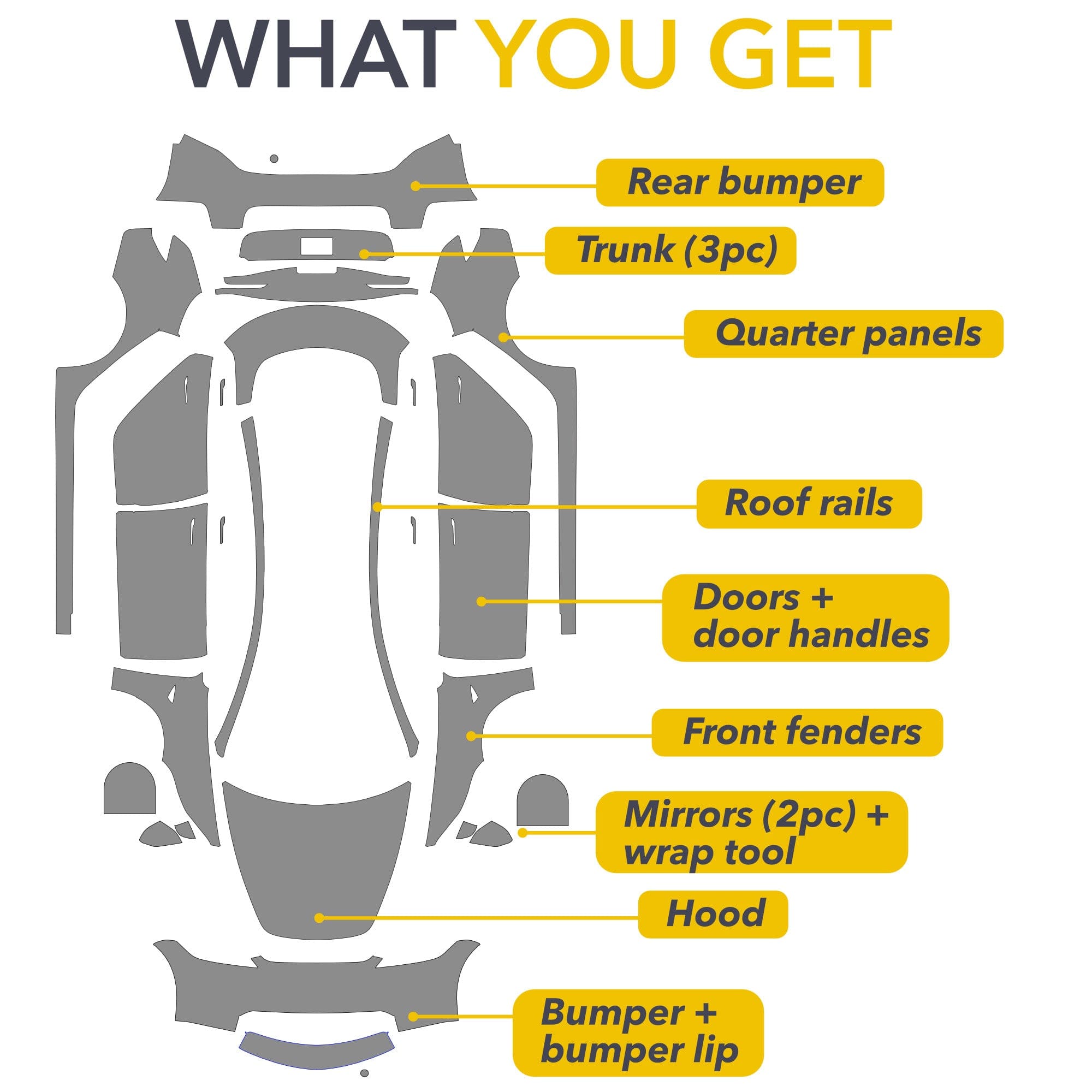

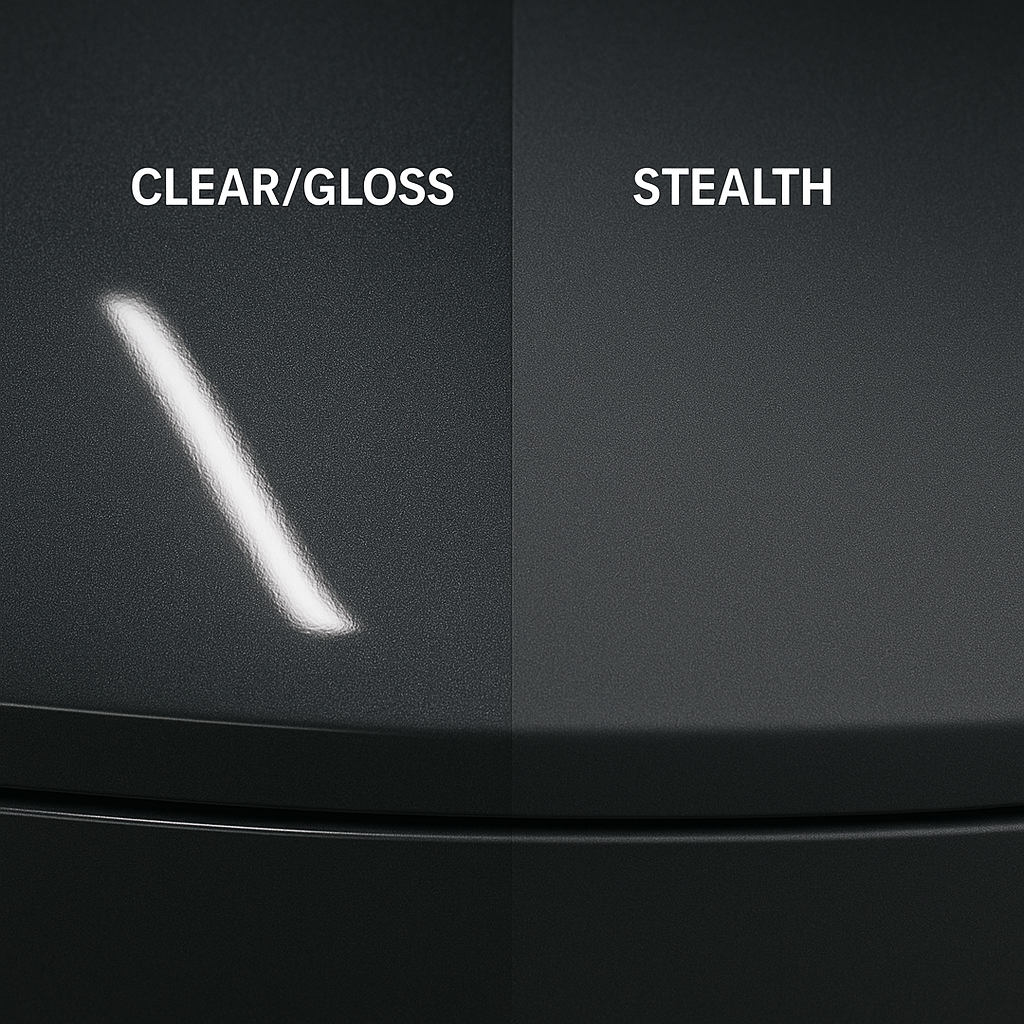

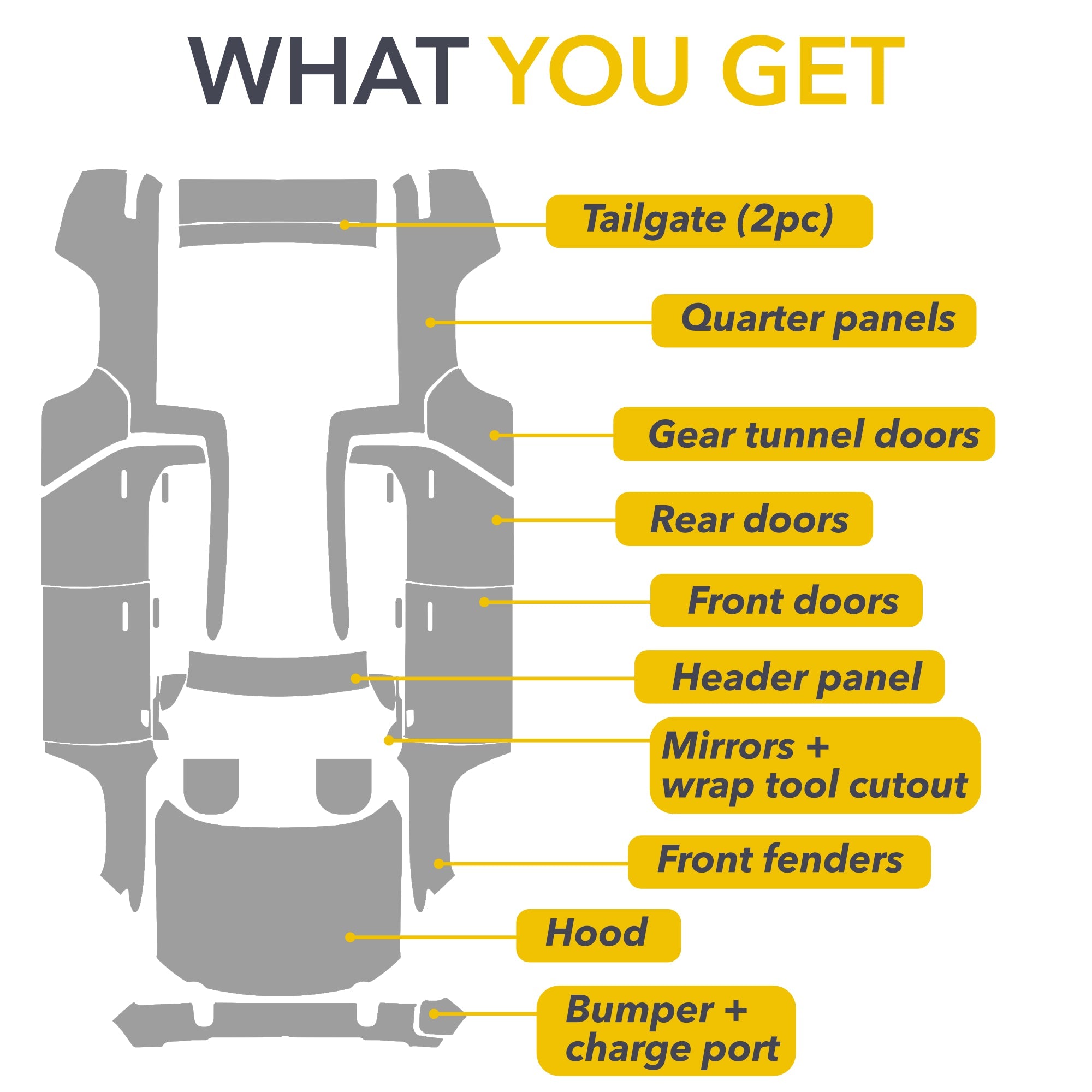

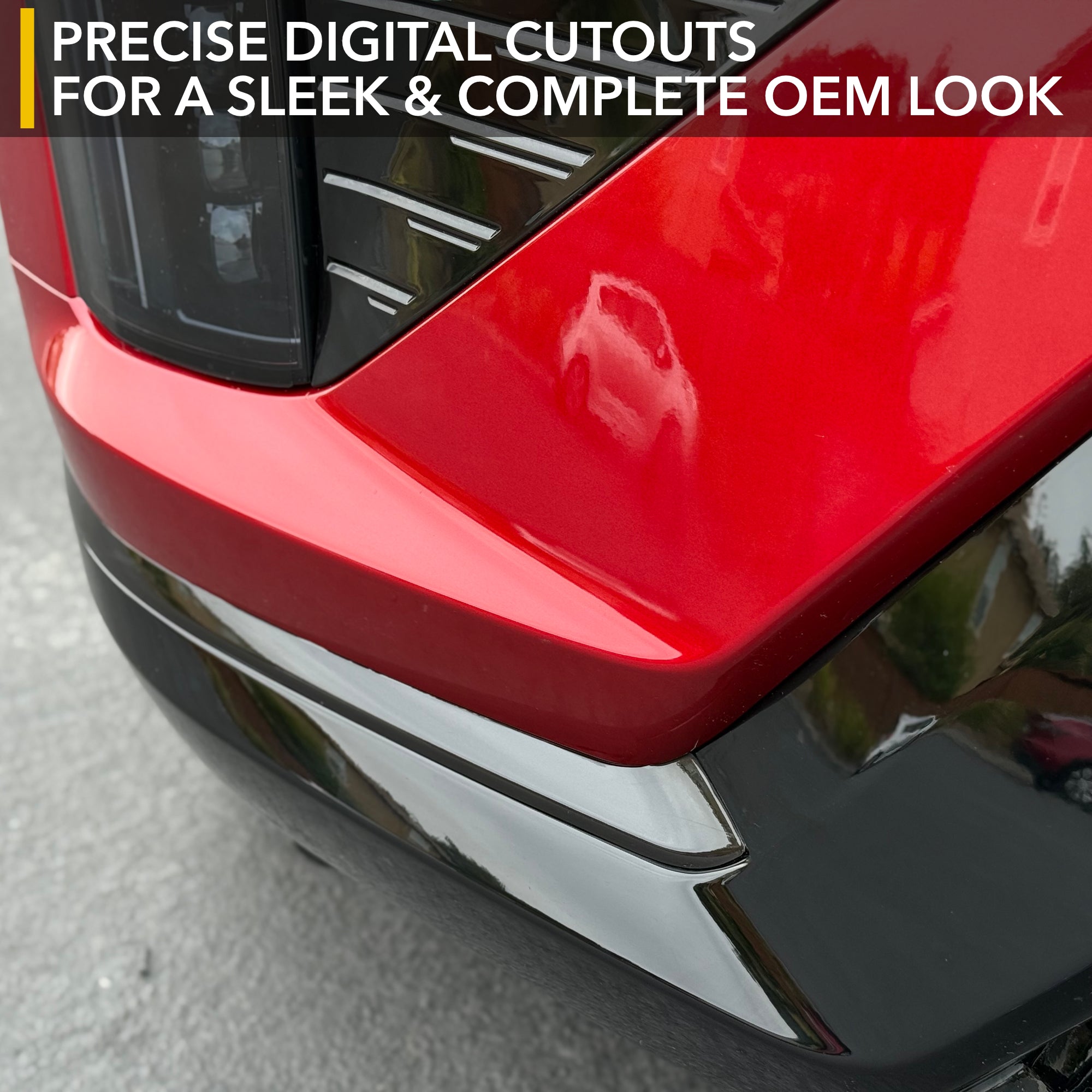

Bespoke wraps are designed in-house with a unique proprietary cut pattern for easy DIY. Made by TWRAPS in 🇺🇸 California.

Browse by vehicle

Latest products

Original products, designed & manufactured by TWRAPS in 🇺🇸 California.

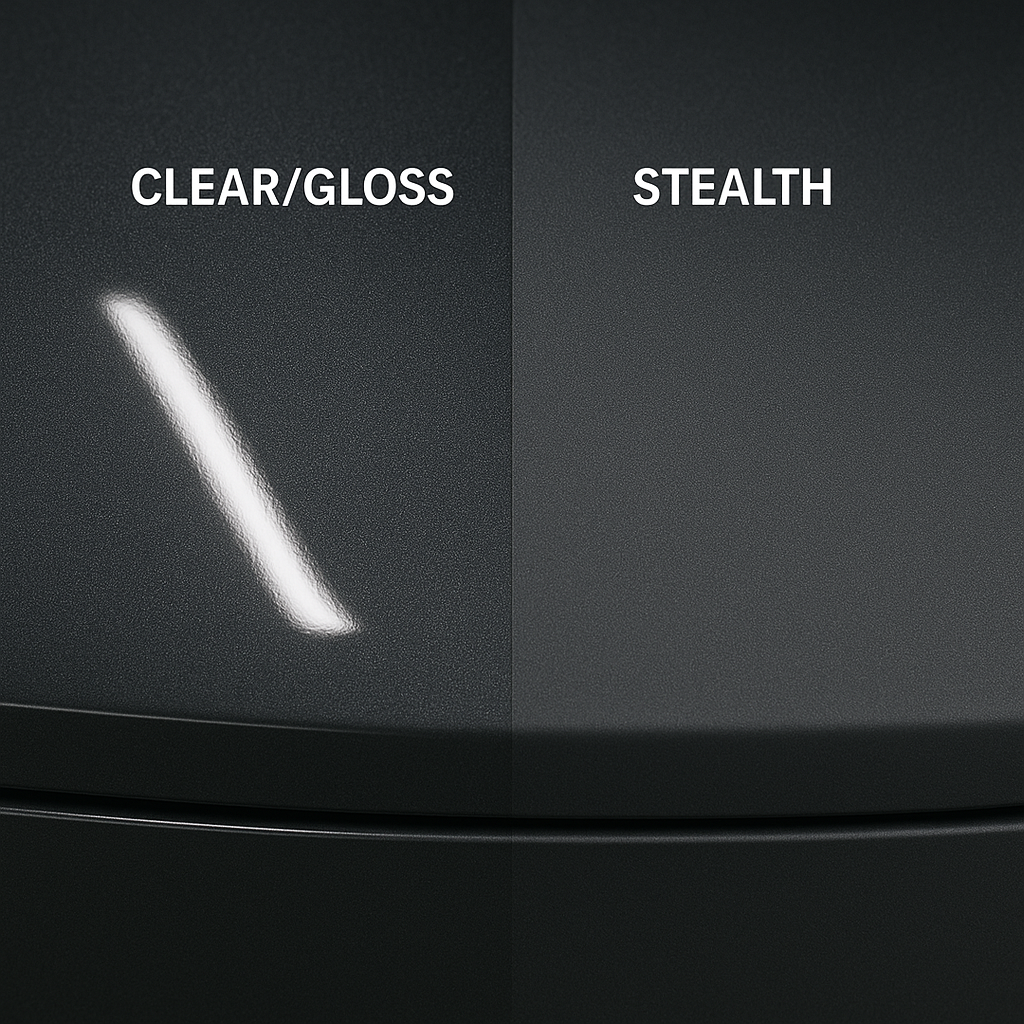

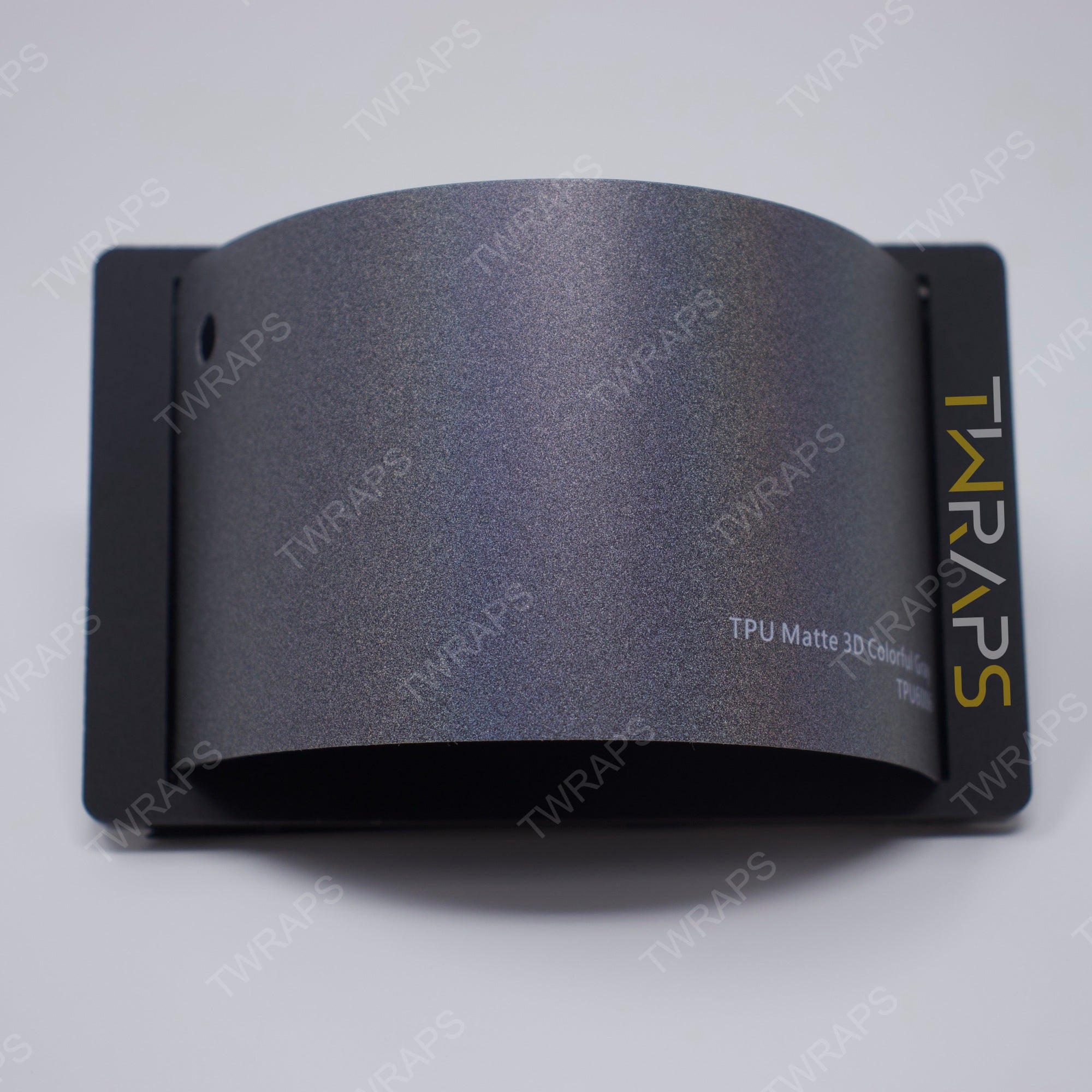

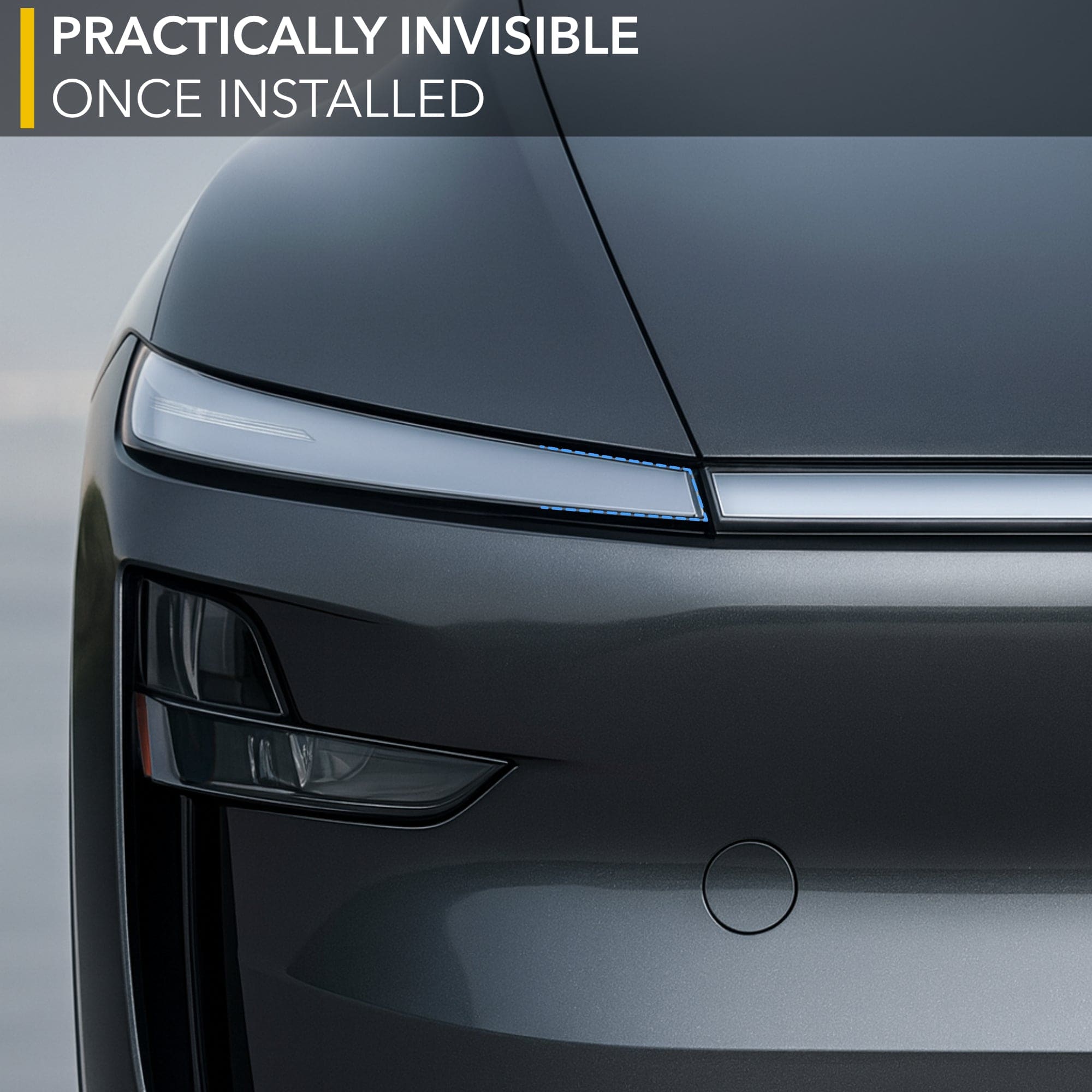

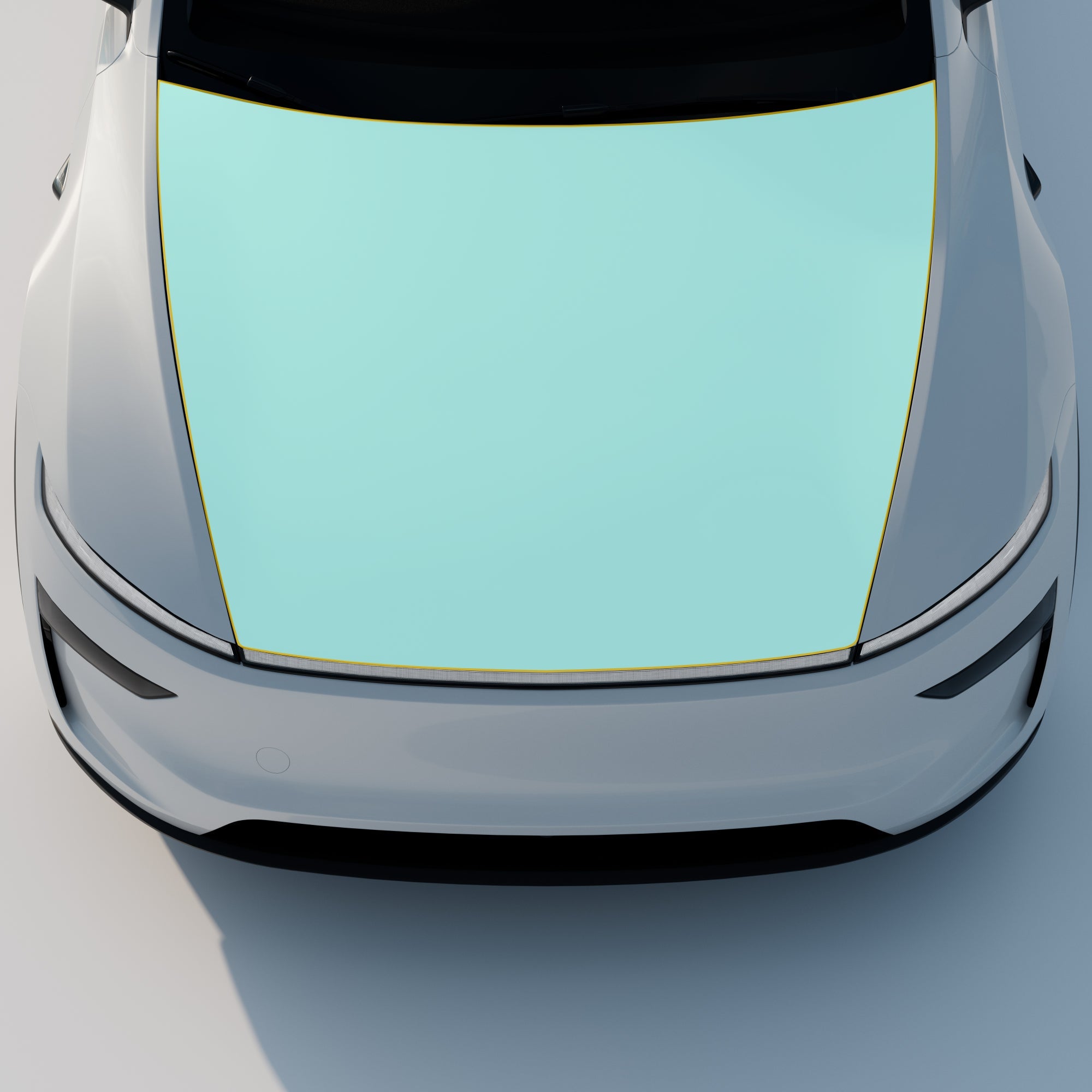

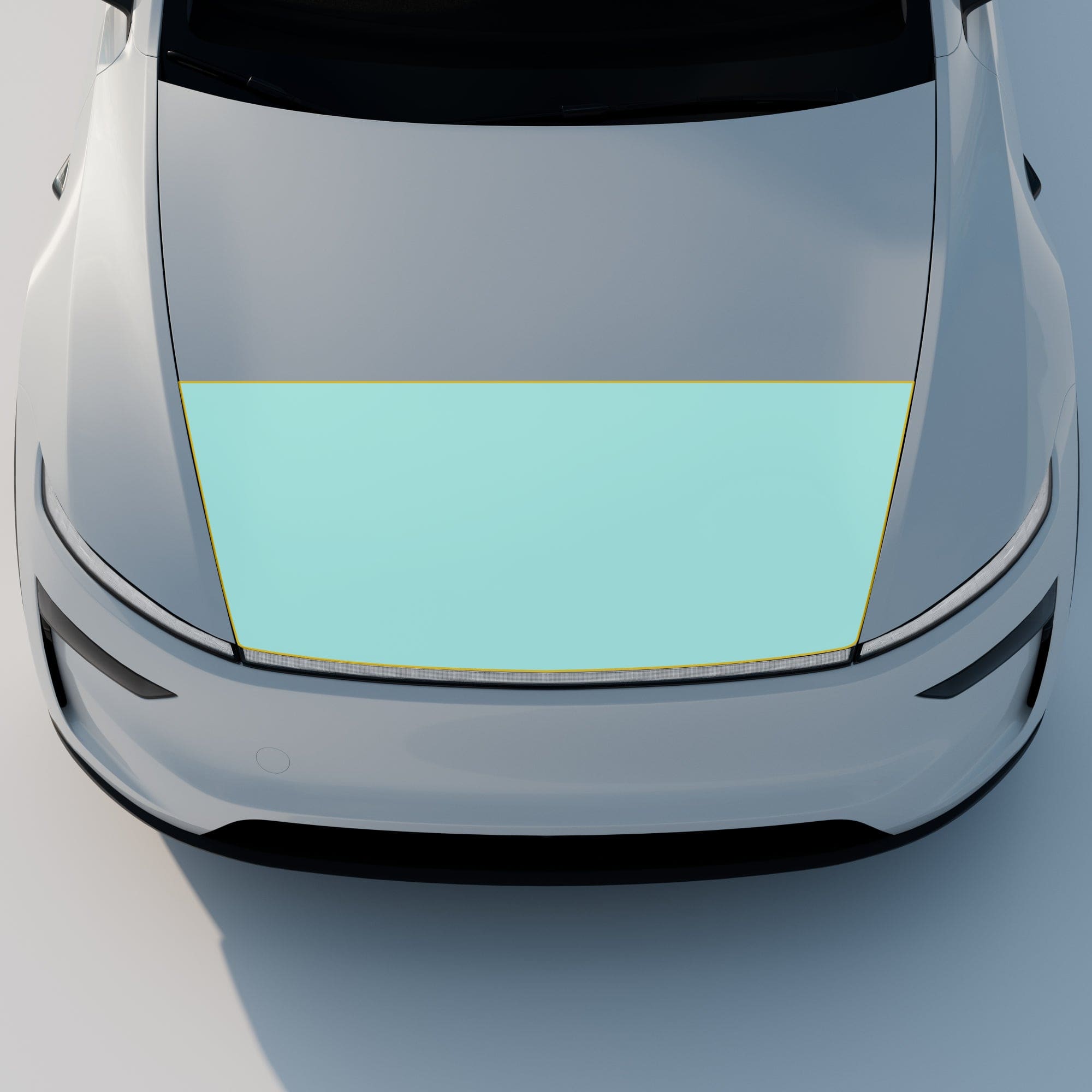

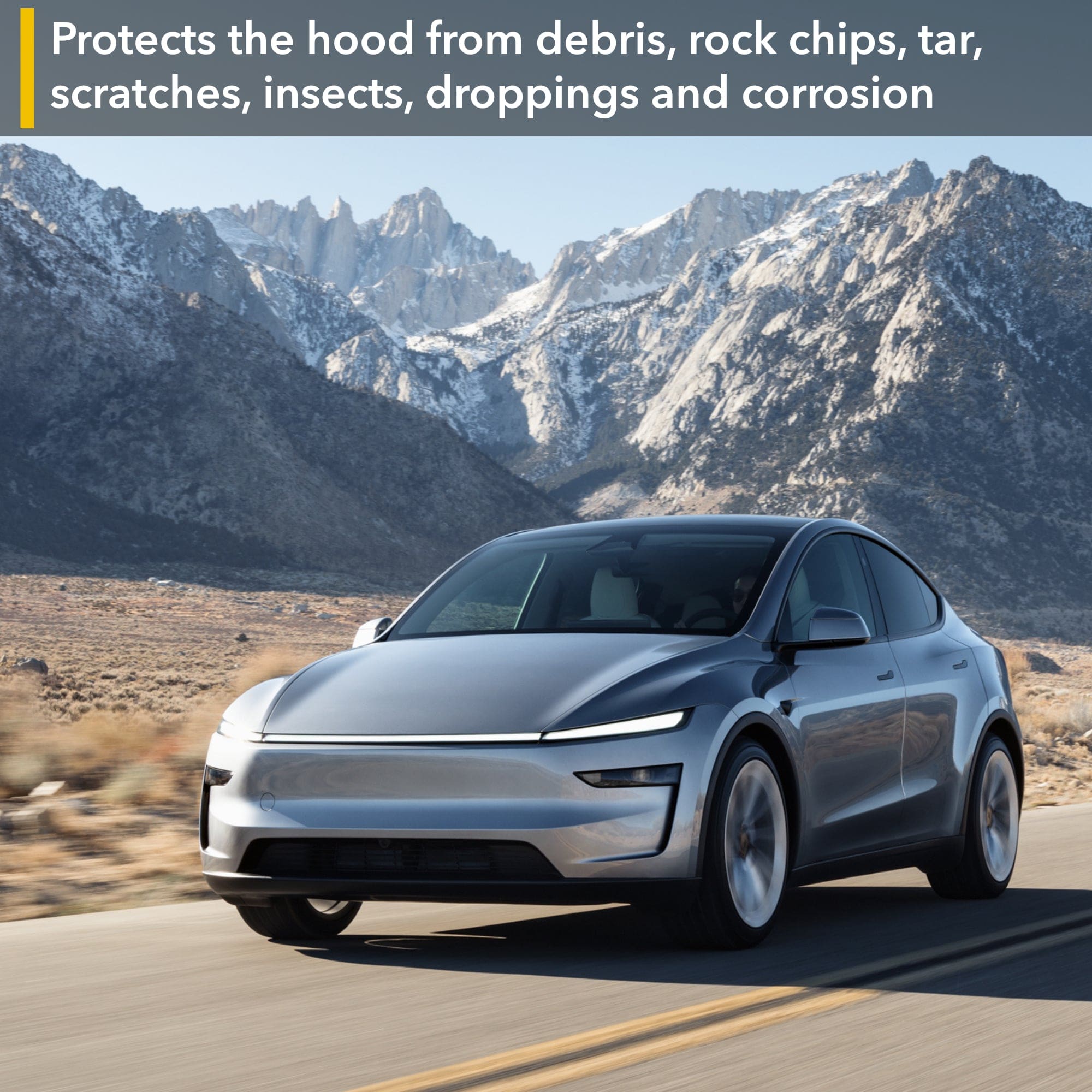

Matte 3D Colorful Gray Color PPF

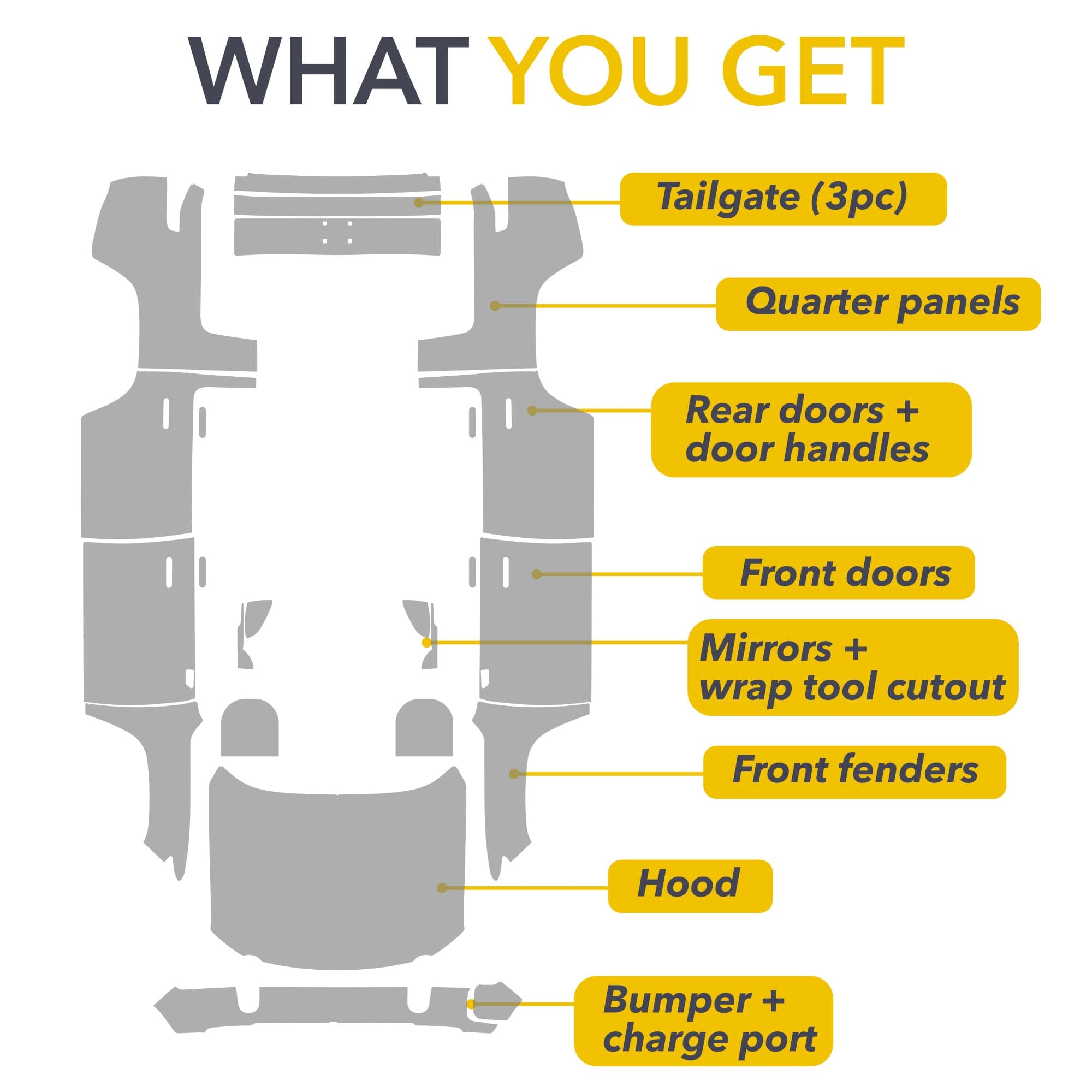

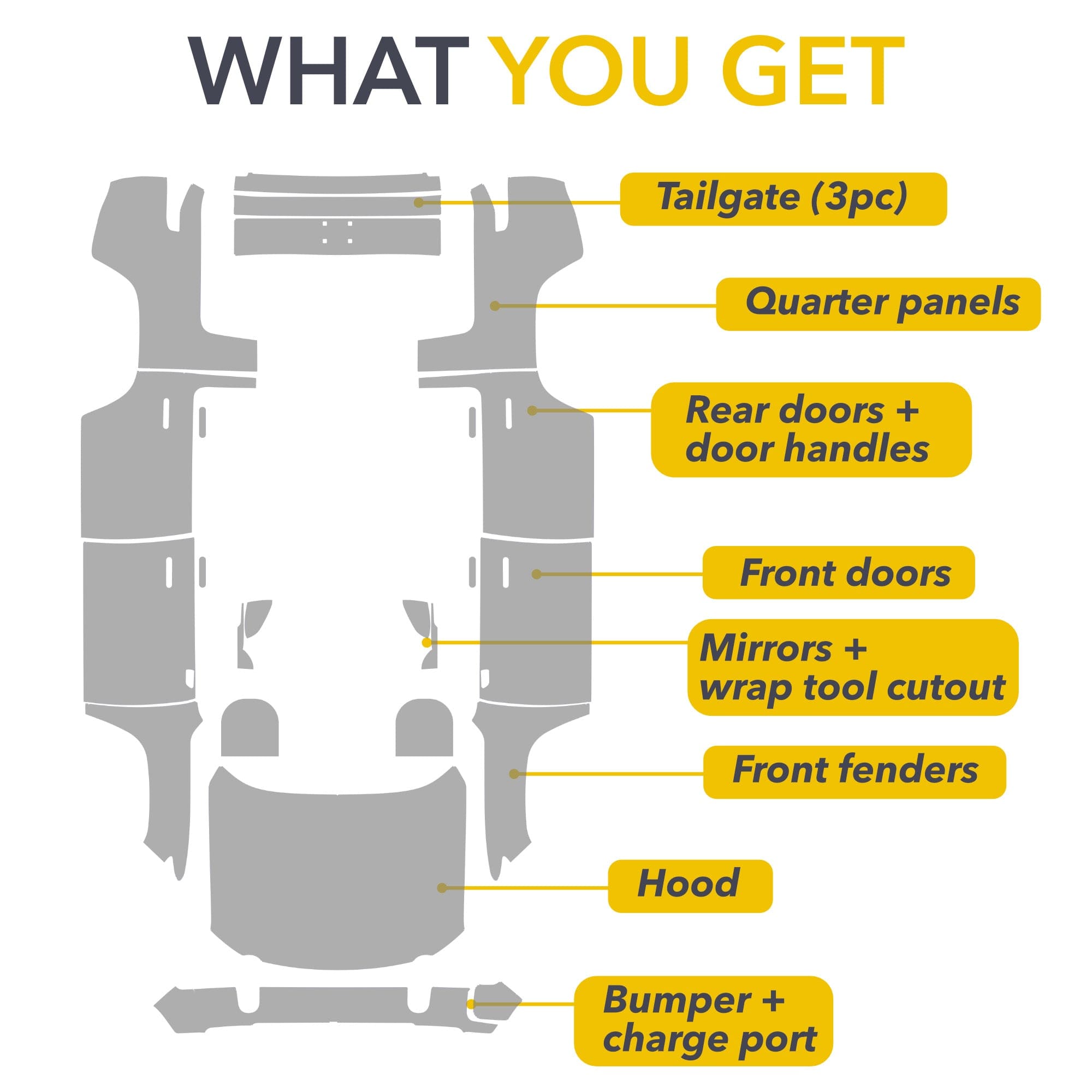

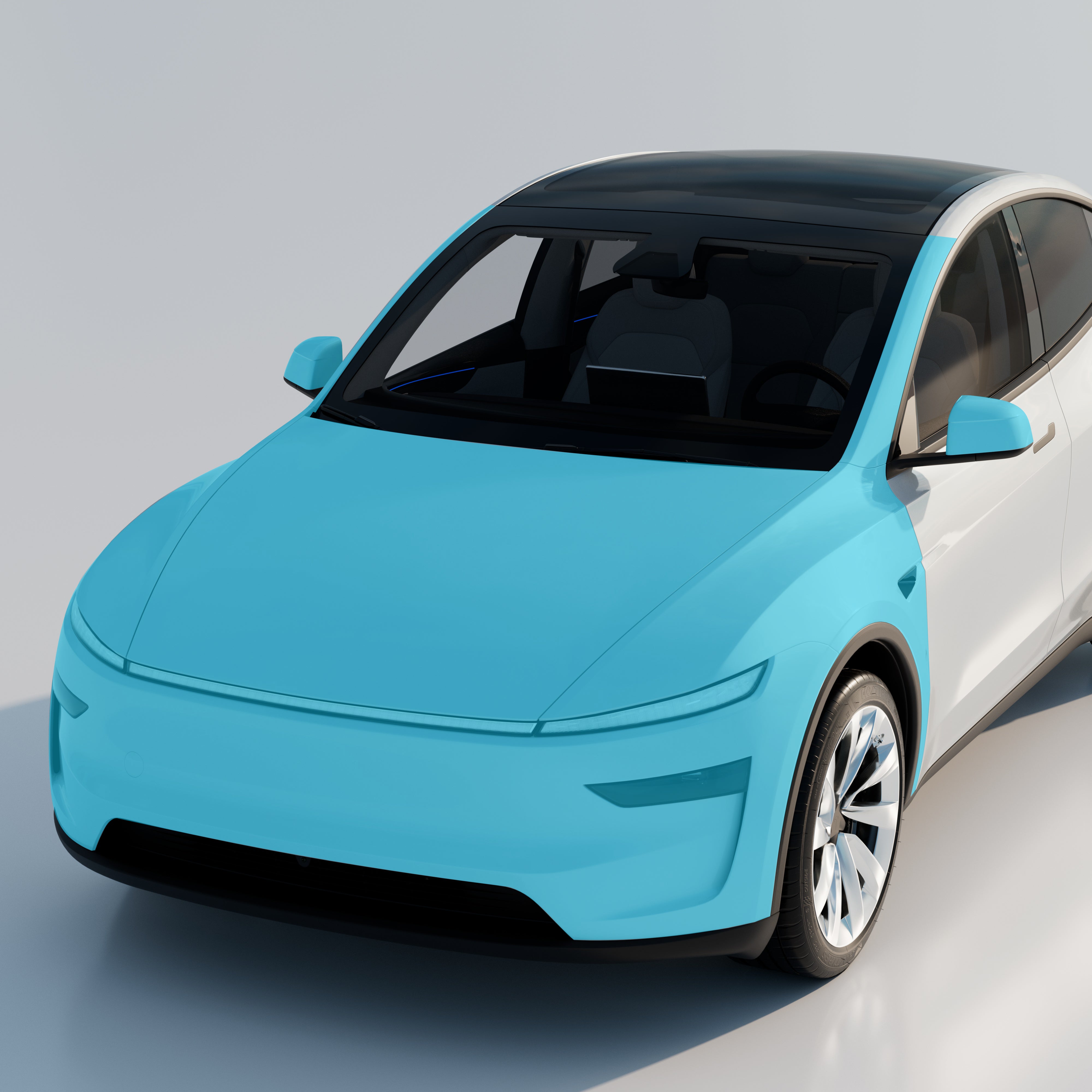

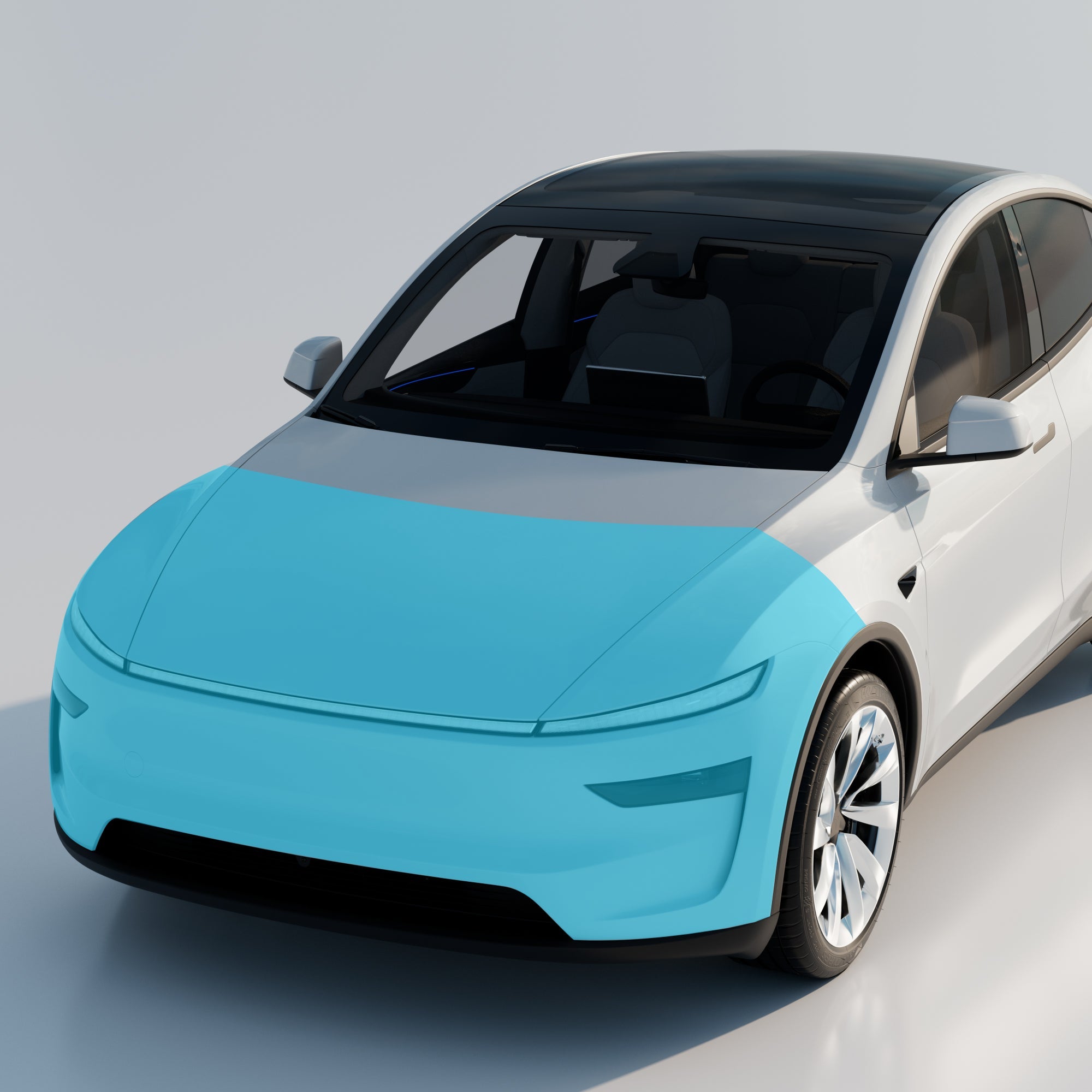

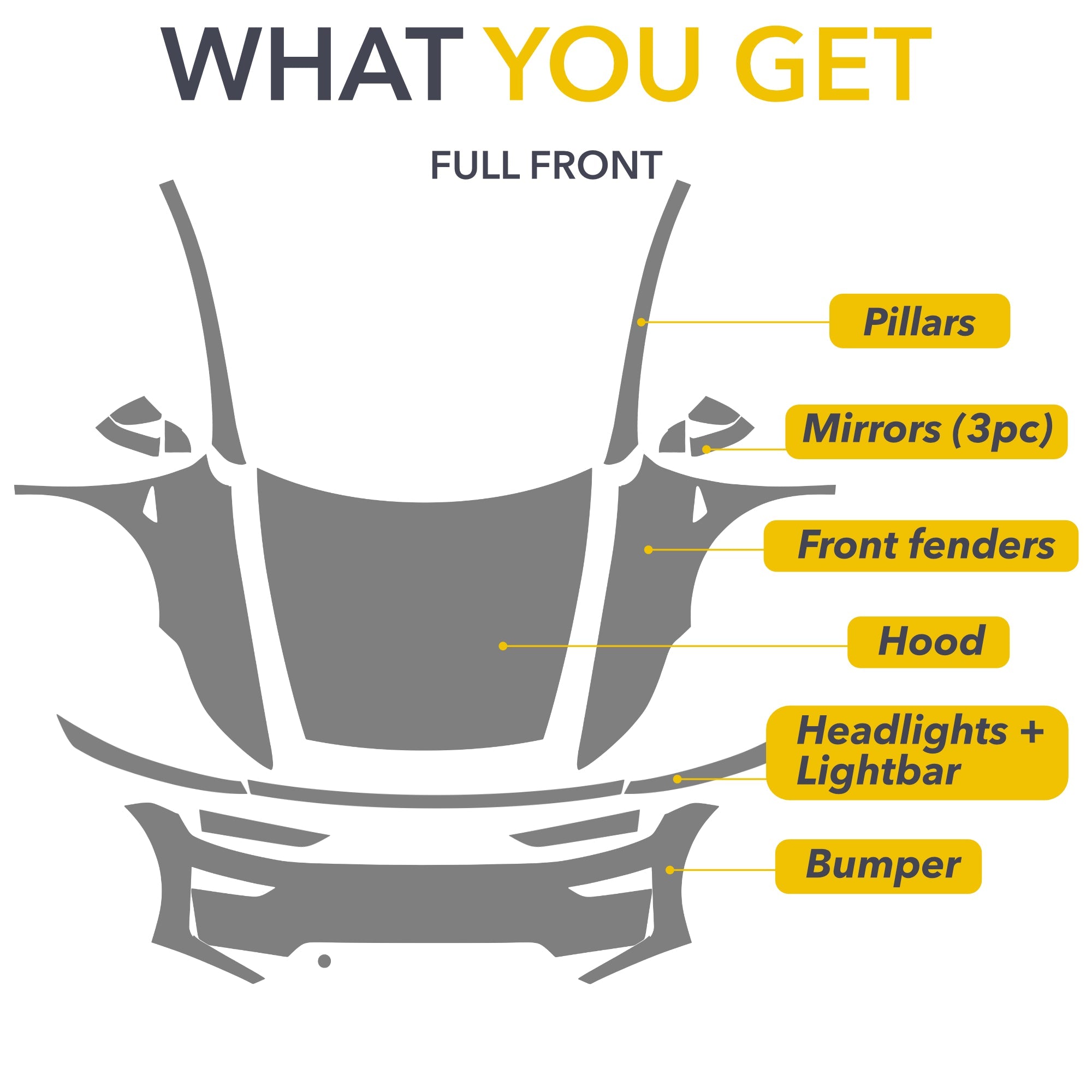

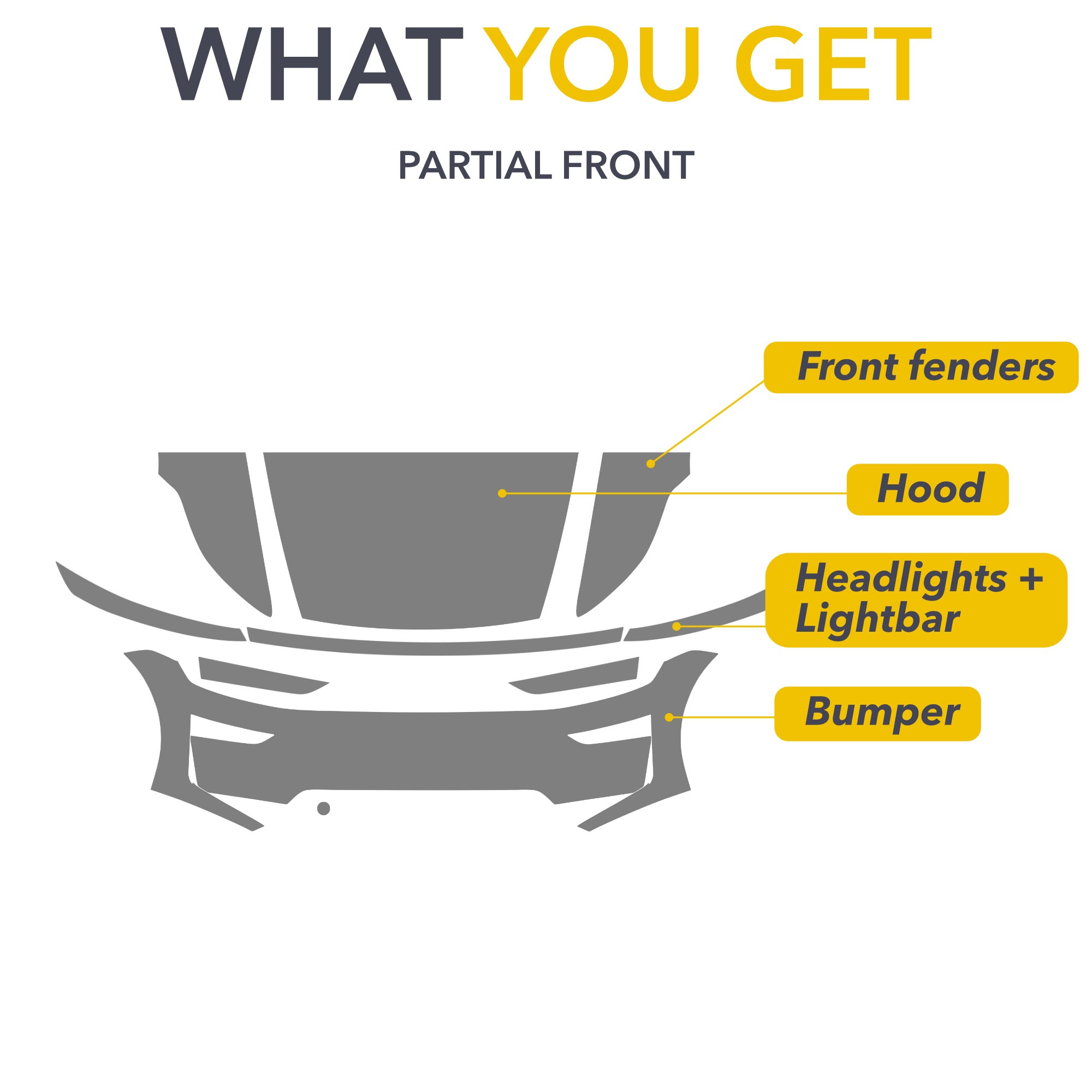

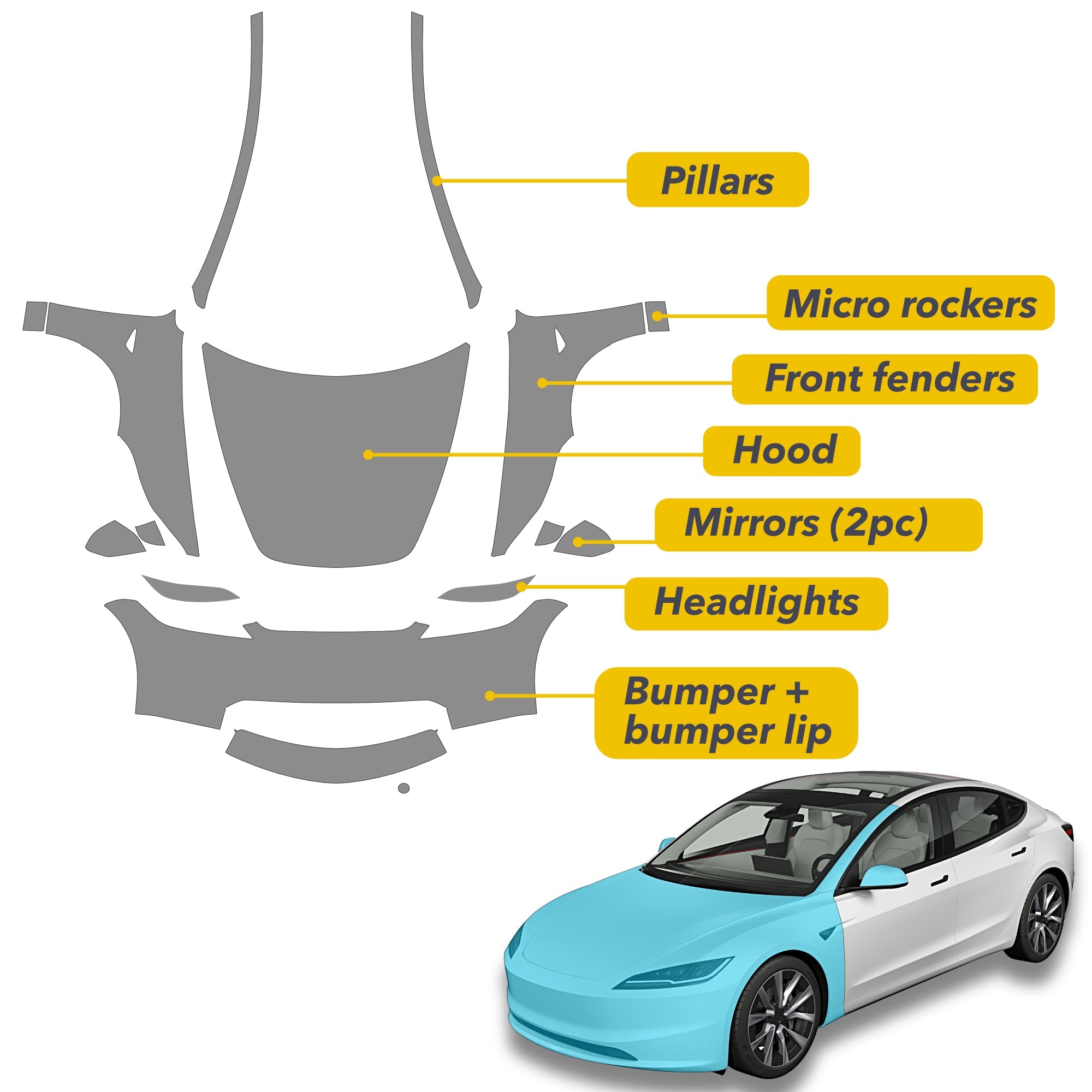

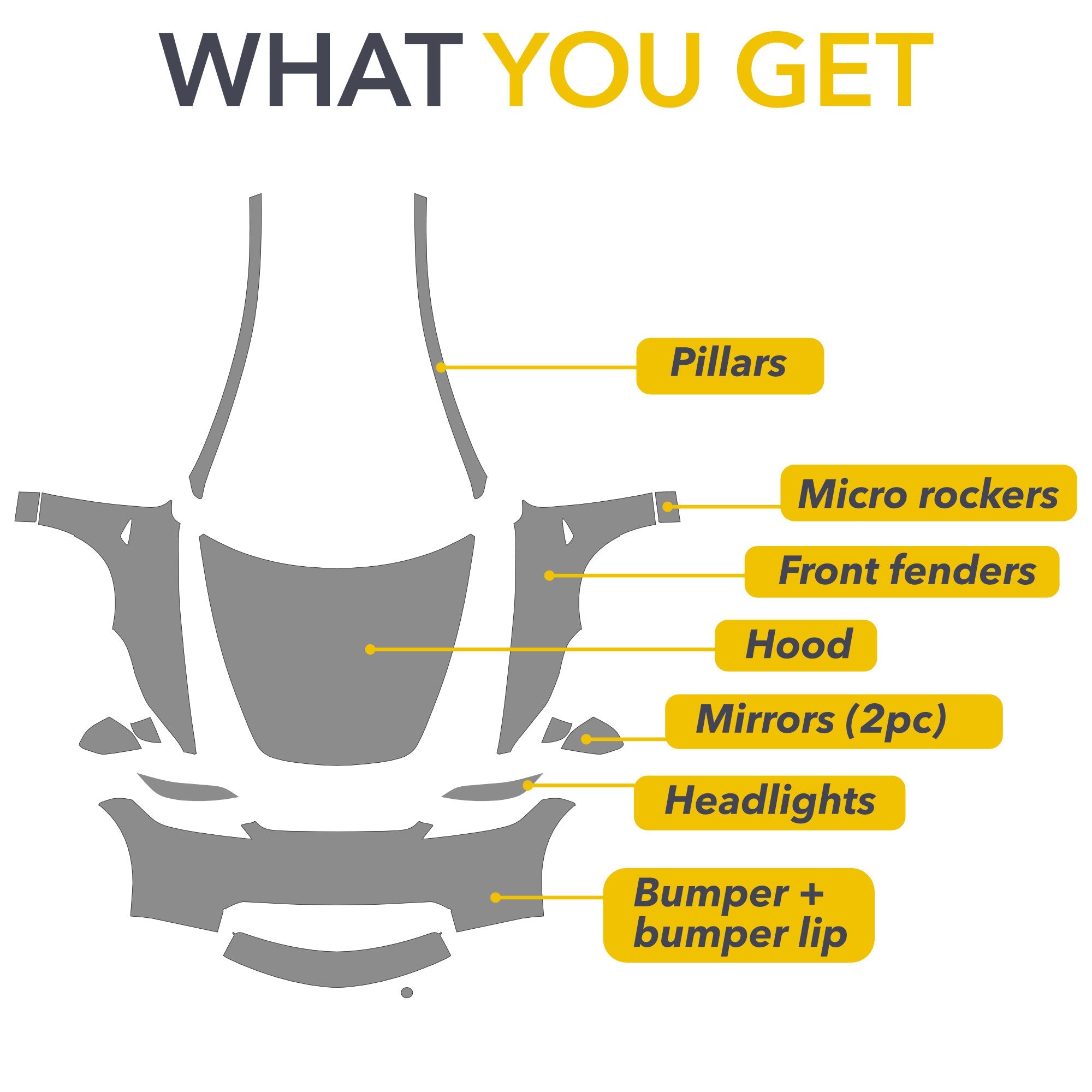

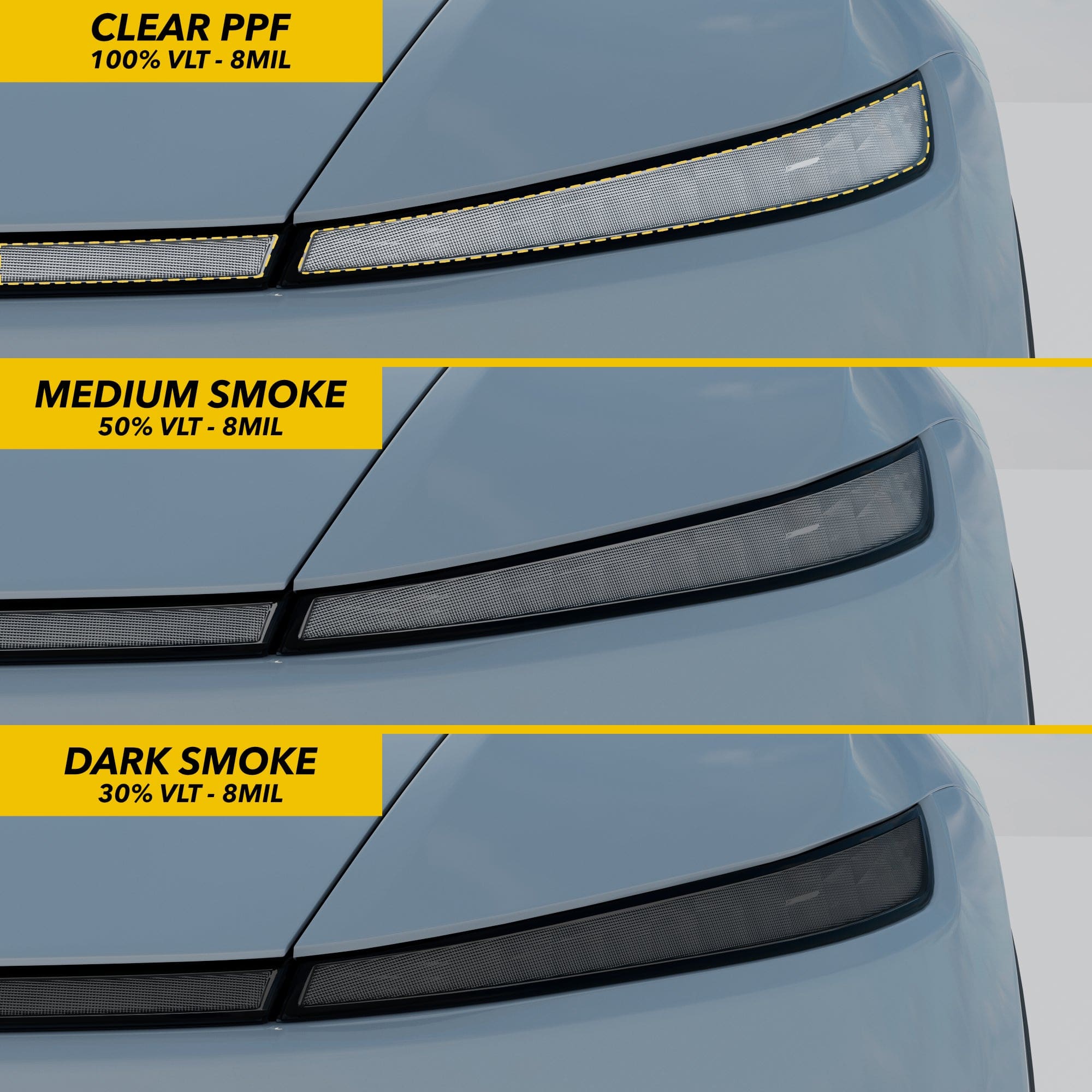

Full/Partial Front Paint Protection Film | for Tesla Model Y Juniper 2026+

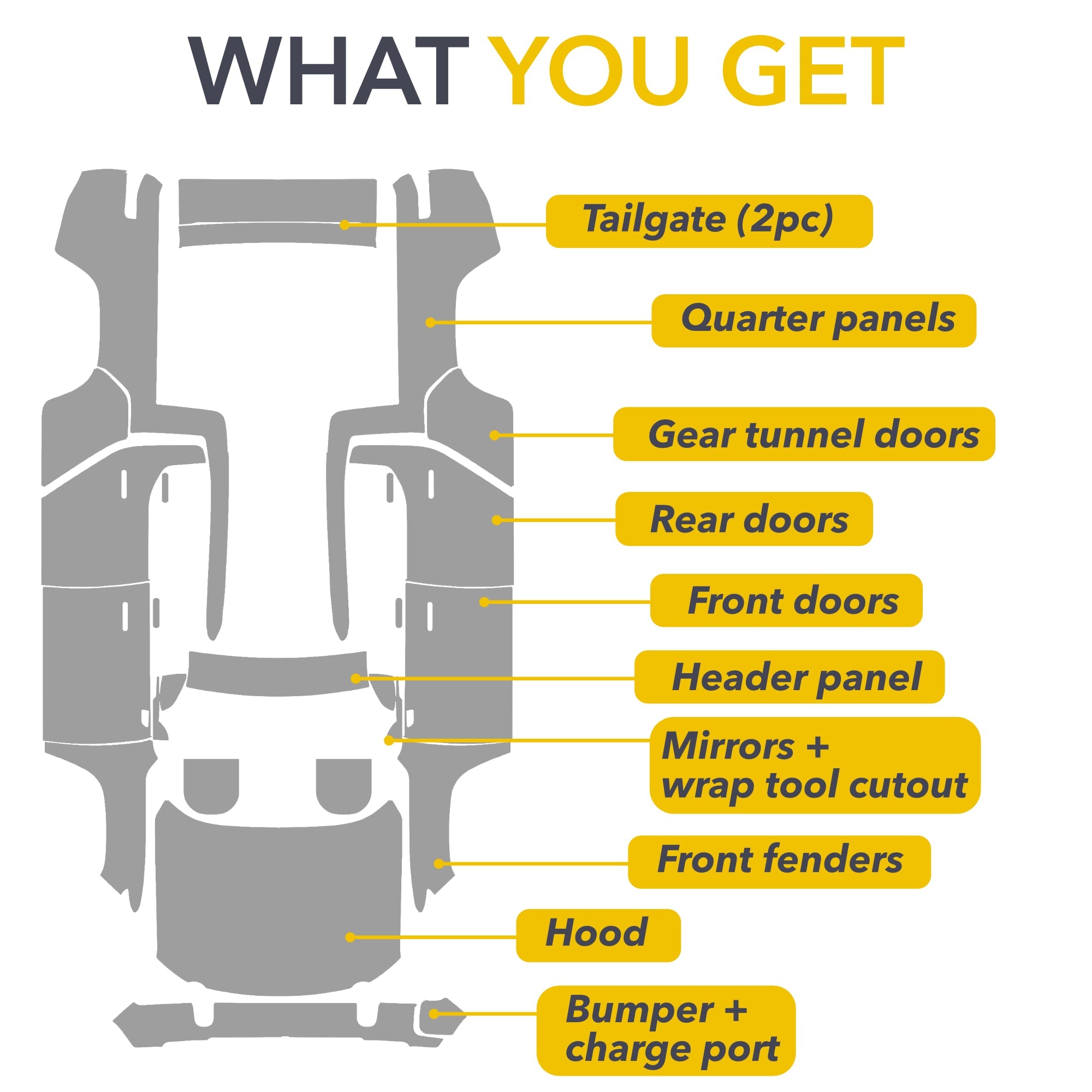

Chrome Delete Blackout Wrap Kit | Cadillac OPTIQ 2023-2026

Let customers speak for us

What customers think about the store

TWraps offers high-quality, well-designed products that are easy to install and provide great protection for vehicles. Their customer service is exceptional, responding promptly to any issues and going above and beyond to ensure customer satisfaction. The prod...