Why Wrap with TWRAPS 8mil PPF

The 8mil PPF protects the vehicle's painted panels from everyday hazards, has a distinct premium glossy look, and maintains the vehicle's appearance pristine for longer due to its self-healing and hydrophobic properties.

Specifications

Stretch Without Distortion or Burn Marks

Specification:

Elongation at break ≥425%; tensile strength ≥25 MPa (≥30 MPa on thicker variants)

Benefit:

The film tolerates aggressive stretching while maintaining surface clarity and uniform thickness. It stays optically stable through compound curves, recessed areas, and edge wrapping when heat is applied correctly.

This won’t happen:

You won’t see whitening, stress lines, or localized haze after stretching mirrors, bumpers, or tight radii.

High Slip, High Control — Fights You Less

Specification:

Peeling force ≥1872 N/25 mm at 20 min; ≥2501 N/25 mm after 24 hr (high-cohesion acrylic PSA)

Benefit:

The adhesive provides a wide working window during install and transitions into strong, consistent bond strength after curing. Repositioning remains predictable without sudden grab or adhesive deformation.

This won’t happen:

You won’t be forced to commit early, fight locked-down sections, or leave adhesive trails from lifting and resetting panels.

Optical Clarity That Doesn’t Die After Stretch

Specification:

Visible light transmittance >90%; haze 0.2–1%; gloss ≥140 GU

Benefit:

Clarity and gloss remain consistent before and after manipulation. The film maintains visual uniformity across panels even where material has been stretched or reheated.

This won’t happen:

You won’t end up with panels that look clear on flat sections but hazy or dull where the film was worked harder.

Real Hydrophobicity (Not Marketing Slickness)

Specification:

Water contact angle ≥103°; dense nano-coating construction

Benefit:

The surface actively resists water and contamination, helping the film stay cleaner between washes and reducing visible spotting during curing and delivery.

This won’t happen:

You won’t see water sheeting flat, trapping grime, or making the finish look tired shortly after install.

Self-Healing That Actually Heals

Specification:

Scratch recovery at 70 °C within 3 minutes under mechanical abrasion testing

Benefit:

The top coat reliably resets from light installation marks, wash marring, and minor surface abrasions with controlled heat or sun exposure.

This won’t happen:

You won’t be stuck explaining permanent squeegee lines, towel marks, or light brush damage to a customer.

Long-Term Stability — No Yellowing, No Edge Failure

Specification:

1000-hour UVA340 accelerated aging test; no yellowing, cracking, or melting (ISO 11507)

Benefit:

The film maintains color stability, elasticity, and structural integrity over time, supporting long-term installs and reducing warranty risk.

This won’t happen:

You won’t see premature yellowing, edge shrinkage, or material breakdown after extended UV exposure.

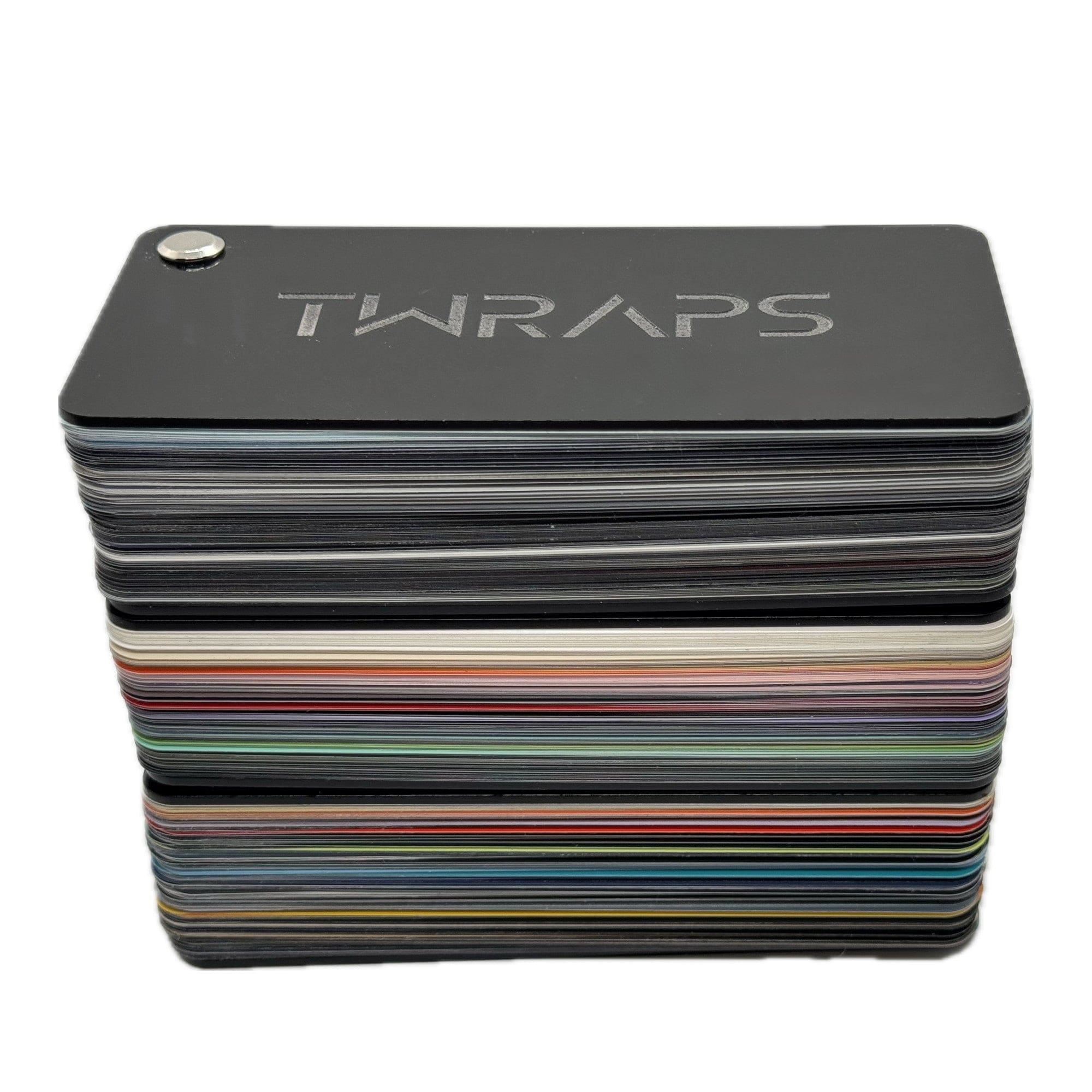

See it in person - rent the swatchbooks

We offer rental on our swatch books that contain over 300 colors. Each color is an actual cut out of the PPF. Rental conditions are simple - return within 30 days of delivery in original condition for a refund minus the cost of shipping. If you also buy a roll of PPF from us or a full pre-cut kit, we will also refund the cost of shipping.

TWRAPS Color PPF Swatch Books (3pc)

No se pudo cargar la disponibilidad de retiro

Retiro disponible en 1990 Olivera Road

Normalmente está listo en 4 horas